1. The machine is controlled by color touch screen, and the main control circuit is high-speed intelligent chip imported from the United States. It has accurate measurement, automatic detection of electrical faults, simple operation and convenient adjustment.

2. Mechanical formula function (memory function: store the debugged program), avoid repeated debugging of products with the same specifications, waste materials, save more time and cost, and improve packaging efficiency

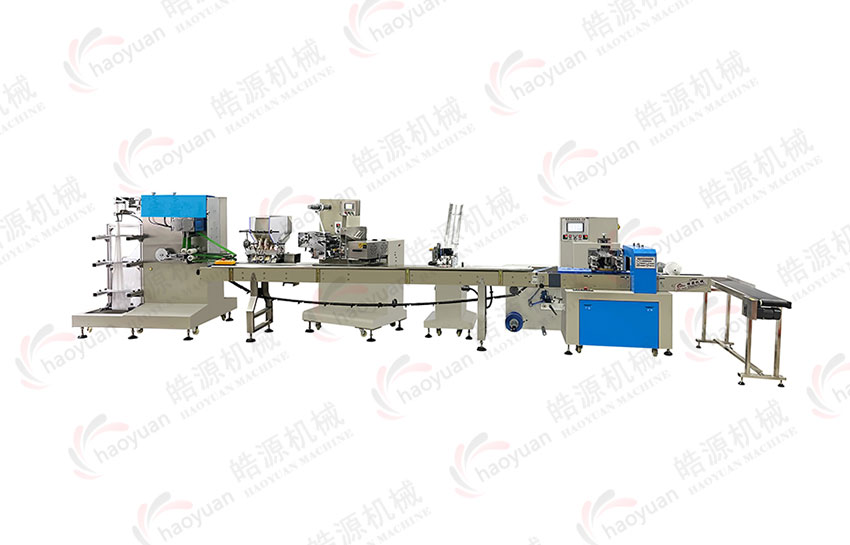

3. The paper towel folding machine and the packaging machine can operate independently (the paper towel folding machine or the packaging machine can be shut down independently at any time).

4. Paper towel blanking, intelligent control by touch screen, no mechanical adjustment

5. Adopt high-quality double frequency conversion and simple mechanical structure, easy to maintain, less wear and long service life.

6. High precision photoelectric detection and tracking (film color mark tracking), bidirectional automatic compensation, accurate and reliable.

7. The bag length can be automatically detected and set without manual setting.

8. The packaging speed and bag forming length are controlled by double frequency converters, with stepless speed change and wide adjustable range, which can perfectly match the previous process of the production line.

9. The conveying table is made of stainless steel, and the main machine is sprayed with plastic and painted at high temperature. It can also be made completely stainless according to customer requirements

中文版

中文版